Sunflower oil extraction process pdf

Sunflower oil extraction process pdf

extraction are the three most common processes for oil recovery from oil seeds. Enzyme based oilseed processing technologies Enzyme based oilseed processing technologies emerge as one of the most eeo-friendly processing methods.

The solvent extraction process generally involves solubilization and partitioning in hexane, separation of the extract, and solvent volatilization and removal to recover the extracted constituents.

Solvent extraction separates the oil from the seeds/beans. The pre-processed The pre-processed seeds/beans are treated in a multistage counter-current process with solvent

A continuous process for the extraction of sunflower oil using supercritical CO 2, featuring multiple extractors, one oil separator and three cascaded CO 2 recovery vessels operating at different pressures, was devised and studied.

A New Approach for Removal of Caffeine from Coffee using Sunflower Oil major advantages of the membrane extraction process are: selectivity, improved productivity, smaller wastes, less energy requirement and availability of large-scale module (i.e. easy scale up methods). In this paper the applicability of sunflower oil (a non-toxic, less costly, environmentally-friendly solvent system

The production process of vegetable oil involves the removal of oil from plant components, typically seeds. This can be done via mechanical extraction using an oil mill or chemical extraction …

process, or expression, involves the use of mechanical power to remove oil from the seed, such as batch hydraulic pressing and continuous mechanical pressing (screw presses). Chemical processes, or extraction, are based in solvent extraction.

Small-scale oil extraction is more commonplace in other parts of the world; thus many of the useful resource materials and much of the appro-priate-scale machinery come from other countries. This publication describes the basic process, with additional details on producing oil from sunflower seeds and sources for additional information. Getting Started Consultant E. Peter Matthies has been

per kg of sunflower oil. However, TOP degumming process can not reduce the amount of P, Mg and Ca under 15.1 mg kg-1, 15.6 mg kg-1 and 3.2 mg kg-1 in extracted rapeseed oil, because of the high content of these elements in initial crude oil. Keywords: degumming, phospholipids, rapeseed oil, sunflower oil, refining Introduction The oil obtained by mechanical expelling or solvent extraction is

sunflower, cottonseed, other oil seeds and oil in cakes like mustard cake, groundnut cake and friendly and generate less effluent. The level Page 1 of 8 bran. output The plants quantity and are ergonomically quality, operator the collets generated from the expander. Solvent Extraction Process The process of solvent extraction results into this purpose. These plants are more efficient

flower, sunflower, grape seed, canola, apricot kernel, coconut, hazelnut, peanut, If you want to process larger amounts of oil-seed crops, a 3-ton to 10-ton per day cage press may be what you want. You can also link multiple cylinder presses in tandem to perform the same function. Another option is the Instapro press, which is a semi-indus-trial-scale press available in the 20-ton per day

1/05/2014 · This could be plant material that has no known antimicrobial effect (for example, a carrier oil such as sunflower oil) at the testing stage. FIGURE 1. Diagram of Soxhlet extraction equipment.

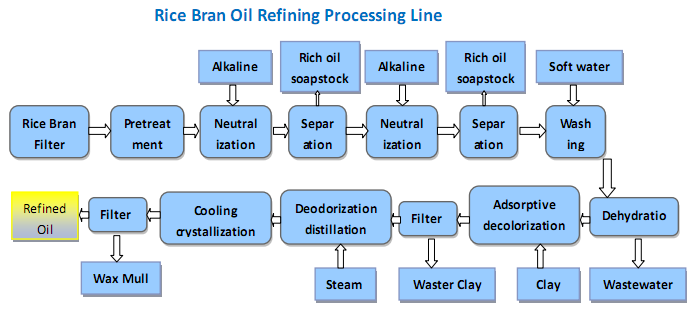

of rice bran oil. And then, optimal process conditions from enzymatic extraction rice bran oil could be obtained by the orthogonal test. RESULTS AND DISCUSSION . Main components of rice bran: The results, the main components of rice bran, were shown in Table 1. Effect on oil yield of rice bran by extraction assisted ultrasonic. Ultrasonic is an elastic mechanical vibration wave. Compression

US8728542B2 Protein preparations from sunflower seeds

INDIAN RICE BRAN OIL INDUSTRY Preface SME

A continuous process for the extraction of sunflower oil using supercritical CO2, featuring multiple extractors, one oil separator and three cascaded CO2 recovery vessels operating at different

Production of biodiesel from sunflower oil and ethanol by base catalysed transesterification Production of biodiesel from sunflower oil and ethanol by base catalyzed transesterification MSc Thesis Alejandro Sales Department of Chemical Engineering Royal Institute of Technology (KTH) Stockholm, Sweden June 2011. Production of biodiesel from sunflower oil and ethanol by base …

Vegetable Oil Production: Industry Profile Preliminary Final Report Prepared for Linda Chappell U.S. Environmental Protection Agency Air Quality Standards and Strategies Division

desirable changes. For example, oil extraction yields from fresh soybeans can be lower than for soybeans stored more than five months. The storage of soybeans also decreases the chlorophyll content of green beans. Chlorophyll is not desirable in edible oils and needs to be removed during the oil refining process. Preparation of Seeds for Oil Extraction Unit operations for preparation of seeds

The crude oil obtained either from expellers or solvent extraction plant contains impurities, which must be removed to make the oil edible, more palatable and stable against rancidity upon storage. The process of removing these impurities is called refining.

The conventional procedure for sunflower oil extraction involves seed preparation, mechanical extraction (in which a press cake or oilcake containing 16–24% of oil is obtained after continuous pressing), and a final stage which is the solvent extraction from ground oilcakes or expanded material, known as “collets” (porous cylinders obtained from pressed sunflower cakes by expanding).

The extraction of sunflower oil is done through exposing the seeds to extreme pressure. Before the extraction can occur, the seeds must undergo preparation. After the extraction has taken place, the oil can be refined further and then continues through various finishing processes.

The ethanolic extraction of oil from sunflower collets was studied and compared with previous data where hexane was used as extraction solvent. First, the extractive power of ethanol was determined by Soxhlet. It gave a higher yield of extracted

Flow chart of the production chain of sunflower seed oil products for feed application in the EU (3 ) C High Little 3 After hexane extraction of the oil and subsequent hexane recovery from the oil, traces of hexane will reside in the crude oil. Feed Marketing Regulation 767/2009 stipulates that feed materials shall be free from chemical impurities resulting from the manufacturing process

Oil extraction Practical Action Some seeds (especially groundnuts for example) are conditioned by heating to 80-90oC using a seed scorcher (Figure 2 shows a typical small-scale example – …

26 1. INTRODUCTION OF THE PRODUCT : Soya bean oil is obtained from the seeds either by pressing or solvent extraction method. It is the highest volume vegetable oil produced.

Extraction of sunflower oil using ethanol as solvent.pdf – Free download as PDF File (.pdf), Text File (.txt) or read online for free. Scribd is the world’s largest social reading and publishing site.

Advantageously the polarity of the extraction solvent is changed through the present residual water after the preliminary treatment, more particularly after mechanical preliminary deoiling and/or during oil extraction, so that during the extraction process with a single added solvent different polarities of the actual extraction mixtures are brought about.

solvent extraction plant process flow diagram note: soybean oil sunflower oil rape seed oil canola oil sesame oil general line soybean seed sunflower seed rape seed canola seed sesame seed crushing dehulling cooking flakes cooling & bagging extractor expander / extruder dtdc recovered solvent extracted soybean / sunflower/ rapeseed / canola / sesame oil doc (cake) cooling / bagging

EHS Guidelines for Vegetable Oil Production and Processing. are applicable to facilities that extract and process oils and fats from a variety of seeds, grains, and nuts; these include canola, castor, cottonseed, mustard, olive, palm, palm-kernel, peanut (groundnut), rapeseed, safflower, sesame, soybean, and sunflower. Additionally covered are crude oil production and refining processes, from

Sunflower seed has been processed by soybean, linseed and cottonseed plants, by direct solvent extraction and by prepress-solvent extraction nlethods.

The extraction process is the same for all eight types of oilseeds subject to this rule (soybean, cottonseed, canola, corn germ Read More. Vegetable oil extraction-offers vegetable oil extraction Vegetable oil extraction is using solvent to extract oil from oil cake, for different capacity , vegetable oil extraction machine and vegetable oil extraction … Read More. Recommend News

Flow chart of the production chain of sunflower seed oil products for feed application in the EU Cultivation of sunflower seeds Drying at primary production

extraction of rapeseed, soybean and sunflower oil using hexane and n-heptane as solvent in order to prove that the shrinking core model could be used for process modelling.

The Environmental Impact of Palm Oil and Other Vegetable an expelling or a solvent extraction process; or a combination of both. The solvent extraction process – with hexane – is commonly used for soyabeans and a combination of both processes for rapeseed and sunflower oil extraction. Expelling after cracking only is applied for

Sunflower processing technique Home – Springer

Technological update on edible oil refining processes Vincent Fiers ‐ Desmet Ballestra Group OFI TECHNICAL/SCIENTIFIC CONFERENCE Tuesday 13th May 2014 Istanbul ‐ Turkey. Edible Oil Refining : Where are we now ? 2 Crude Oil Water degumming Alkali ANeutralisation Deod orization Refined Oil Soapstock Spent bleaching earth Deodorizer Distillate Mechanical Pressing OILSEEDS Oil Extraction

Sunflower seeds come in 2 types: the non-oil seeds that are eaten as confectionery products after roasted with the shell or without the shell as kernels, and the oilseeds that are processed into oil and meal which is a by-product of sunflower seed oil extraction primarily used as …

Oil production requires some type of press with which to extract the oil form the groundnuts and filtering equipment. ITDG has developed a simple manual screw press that would be suitable for

Sunflower meal is the by-product of the extraction of oil from sunflower seeds. In terms of production, it is the 4th most important oil meal after soybean meal, rapeseed meal and cottonseed meal (Oil …

Edible oils and fats are produced either by solvent or mechanical extraction of oilseeds or oil-bearing plant and animal materials or by heat rendering of animal tissues. – candy bar bouquet instructions Cooking oil manufacture involves cleaning the seeds, grinding them, pressing, and extrading the oil from them. In extracting, a volatile hydrocarbon such as hexane is used as a solvent. In extracting, a volatile hydrocarbon such as hexane is used as a solvent.

Continuous Solvent Extraction Process is to extract oil from bearing materials with the help of Solvent/chemical called normal-Hexane . This process is having the following stages in …

Desmet Ballestra, a leader in oil extraction technologies. P A T E N T I S S U E D Solvent Extraction The seed, having been properly prepared, is separated into a crude oil fraction and a protein meal fraction by solvent extraction. The extractor utilizes a countercurrent, multi-stage washing with commercial hexane solvent to enable a reasonable quantity of solvent to extract a maximum

PRINCIPLES OF OIL EXTRACTION Oil is extracted from a number of fruits, nuts and seeds (Table 1) for use in cooking and soapmaking1 or as an ingredient in other foods such as baked or fried goods.

Oil press machine (oil expeller press) is the soul equipment of the pressing process, it can be divided into small oil press and big oil press according to its capacity, it can also be put into screw oil press and hydraulic oil press as to its working principle. In comparison with the hydraulic oil press, the screw type expeller press has a great deal advantages, For example, better

Oil pressing is a mechanical method for oil extraction from oleaginous materials. For the oil extraction from oilseeds are used generally horizontal screw presses with one or two discharge ends

preferred process for sunflower seedoil extraction. This process leaves a high amount of oil in the seeds, which is wasteful and unprofitable. has SFT developed a lab scale process to extract pure sunflower seed oil utilizing supercritical carbon dioxideand the SFT-110 SFE. This process yields completely “pure” sunflower oil. First, SFT determined the general solubility parameters of the

Based on seed crushing and solvent extraction, the process can be applied to a wide range of feedstocks. Flexible technology Sliding Cell Extractor from Air Liquide Engineering & Construction uses a feedstock of oil seeds such as soybean, canola/rapeseed, sunflower and palm kernel.

Sunflower Seeds Oil Extract Machine – Manufacturers, Suppliers . 12365 products About 98% of these are oil pressers, 1% are other farm machines, and 1% are small neem sunflower seed oil processing extraction machine dewaxing coconut palm kernel hemp castor oil cold press sunflower seed

SUNFLOWER SECTOR DEVELOPMENT STRATEGY 2016-2020 . II UNITED EPULIC O TANANIA SUNLOWE SECTO DEVELOPENT STATEY This sector development strategy was developed on the basis of the process, methodology and technical assistance of the International Trade Centre (ITC) within the framework of its Trade Development Strategy programme. ITC is the joint agency of the …

Project Profile msmedi-agartala.nic.in

rapeseed oil extraction process oil seed press machine

Groundnut Processing United Diversity

Oil Presses Embrapa

Extraction of sunflower oil using ethanol as solvent.pdf

22 REGULATORYAFFAIRS ARTICLE January 2004 Volume 15 (1

Desmet Ballestra

https://en.wikipedia.org/wiki/Vegetable_oil

SUNFLOWER OIL EXTRACTION USING SUPERCRITICAL FLUIDS

ferrero rocher bouquet tutorial – Oil extraction Process Rapeseed Distillation

SOLVENT EXTRACTION PLANT PROCESS FLOW DIAGRAM

Study on the Preparation Process of Rice Bran Oil by the

Oilseed Processing for Small-Scale Producers

SUNFLOWER SECTOR DEVELOPMENT STRATEGY 2016-2020

FOOD TECHNOLOGY pods.dasnr.okstate.edu

The production process of vegetable oil involves the removal of oil from plant components, typically seeds. This can be done via mechanical extraction using an oil mill or chemical extraction …

Oil extraction Practical Action Some seeds (especially groundnuts for example) are conditioned by heating to 80-90oC using a seed scorcher (Figure 2 shows a typical small-scale example – …

Small-scale oil extraction is more commonplace in other parts of the world; thus many of the useful resource materials and much of the appro-priate-scale machinery come from other countries. This publication describes the basic process, with additional details on producing oil from sunflower seeds and sources for additional information. Getting Started Consultant E. Peter Matthies has been

Edible oils and fats are produced either by solvent or mechanical extraction of oilseeds or oil-bearing plant and animal materials or by heat rendering of animal tissues.

flower, sunflower, grape seed, canola, apricot kernel, coconut, hazelnut, peanut, If you want to process larger amounts of oil-seed crops, a 3-ton to 10-ton per day cage press may be what you want. You can also link multiple cylinder presses in tandem to perform the same function. Another option is the Instapro press, which is a semi-indus-trial-scale press available in the 20-ton per day

1/05/2014 · This could be plant material that has no known antimicrobial effect (for example, a carrier oil such as sunflower oil) at the testing stage. FIGURE 1. Diagram of Soxhlet extraction equipment.

Cooking oil manufacture involves cleaning the seeds, grinding them, pressing, and extrading the oil from them. In extracting, a volatile hydrocarbon such as hexane is used as a solvent. In extracting, a volatile hydrocarbon such as hexane is used as a solvent.

Flow chart of the production chain of sunflower seed oil products for feed application in the EU (3 ) C High Little 3 After hexane extraction of the oil and subsequent hexane recovery from the oil, traces of hexane will reside in the crude oil. Feed Marketing Regulation 767/2009 stipulates that feed materials shall be free from chemical impurities resulting from the manufacturing process

desirable changes. For example, oil extraction yields from fresh soybeans can be lower than for soybeans stored more than five months. The storage of soybeans also decreases the chlorophyll content of green beans. Chlorophyll is not desirable in edible oils and needs to be removed during the oil refining process. Preparation of Seeds for Oil Extraction Unit operations for preparation of seeds

preferred process for sunflower seedoil extraction. This process leaves a high amount of oil in the seeds, which is wasteful and unprofitable. has SFT developed a lab scale process to extract pure sunflower seed oil utilizing supercritical carbon dioxideand the SFT-110 SFE. This process yields completely “pure” sunflower oil. First, SFT determined the general solubility parameters of the

Based on seed crushing and solvent extraction, the process can be applied to a wide range of feedstocks. Flexible technology Sliding Cell Extractor from Air Liquide Engineering & Construction uses a feedstock of oil seeds such as soybean, canola/rapeseed, sunflower and palm kernel.

A continuous process for the extraction of sunflower oil using supercritical CO2, featuring multiple extractors, one oil separator and three cascaded CO2 recovery vessels operating at different

Extraction of sunflower oil using ethanol as solvent.pdf – Free download as PDF File (.pdf), Text File (.txt) or read online for free. Scribd is the world’s largest social reading and publishing site.

A New Approach for Removal of Caffeine from Coffee using Sunflower Oil major advantages of the membrane extraction process are: selectivity, improved productivity, smaller wastes, less energy requirement and availability of large-scale module (i.e. easy scale up methods). In this paper the applicability of sunflower oil (a non-toxic, less costly, environmentally-friendly solvent system

Flow chart of the production chain of sunflower seed oil products for feed application in the EU Cultivation of sunflower seeds Drying at primary production

Extraction of sunflower oil using ethanol as solvent.pdf

22 REGULATORYAFFAIRS ARTICLE January 2004 Volume 15 (1

The crude oil obtained either from expellers or solvent extraction plant contains impurities, which must be removed to make the oil edible, more palatable and stable against rancidity upon storage. The process of removing these impurities is called refining.

flower, sunflower, grape seed, canola, apricot kernel, coconut, hazelnut, peanut, If you want to process larger amounts of oil-seed crops, a 3-ton to 10-ton per day cage press may be what you want. You can also link multiple cylinder presses in tandem to perform the same function. Another option is the Instapro press, which is a semi-indus-trial-scale press available in the 20-ton per day

desirable changes. For example, oil extraction yields from fresh soybeans can be lower than for soybeans stored more than five months. The storage of soybeans also decreases the chlorophyll content of green beans. Chlorophyll is not desirable in edible oils and needs to be removed during the oil refining process. Preparation of Seeds for Oil Extraction Unit operations for preparation of seeds

Based on seed crushing and solvent extraction, the process can be applied to a wide range of feedstocks. Flexible technology Sliding Cell Extractor from Air Liquide Engineering & Construction uses a feedstock of oil seeds such as soybean, canola/rapeseed, sunflower and palm kernel.

Oil extraction Practical Action Some seeds (especially groundnuts for example) are conditioned by heating to 80-90oC using a seed scorcher (Figure 2 shows a typical small-scale example – …

1/05/2014 · This could be plant material that has no known antimicrobial effect (for example, a carrier oil such as sunflower oil) at the testing stage. FIGURE 1. Diagram of Soxhlet extraction equipment.

SUNFLOWER SECTOR DEVELOPMENT STRATEGY 2016-2020

Extraction of sunflower oil using ethanol as solvent

A continuous process for the extraction of sunflower oil using supercritical CO2, featuring multiple extractors, one oil separator and three cascaded CO2 recovery vessels operating at different

Small-scale oil extraction is more commonplace in other parts of the world; thus many of the useful resource materials and much of the appro-priate-scale machinery come from other countries. This publication describes the basic process, with additional details on producing oil from sunflower seeds and sources for additional information. Getting Started Consultant E. Peter Matthies has been

Sunflower meal is the by-product of the extraction of oil from sunflower seeds. In terms of production, it is the 4th most important oil meal after soybean meal, rapeseed meal and cottonseed meal (Oil …

Flow chart of the production chain of sunflower seed oil products for feed application in the EU (3 ) C High Little 3 After hexane extraction of the oil and subsequent hexane recovery from the oil, traces of hexane will reside in the crude oil. Feed Marketing Regulation 767/2009 stipulates that feed materials shall be free from chemical impurities resulting from the manufacturing process

Advantageously the polarity of the extraction solvent is changed through the present residual water after the preliminary treatment, more particularly after mechanical preliminary deoiling and/or during oil extraction, so that during the extraction process with a single added solvent different polarities of the actual extraction mixtures are brought about.

The crude oil obtained either from expellers or solvent extraction plant contains impurities, which must be removed to make the oil edible, more palatable and stable against rancidity upon storage. The process of removing these impurities is called refining.

Oil pressing is a mechanical method for oil extraction from oleaginous materials. For the oil extraction from oilseeds are used generally horizontal screw presses with one or two discharge ends

Edible oils and fats are produced either by solvent or mechanical extraction of oilseeds or oil-bearing plant and animal materials or by heat rendering of animal tissues.

The extraction process is the same for all eight types of oilseeds subject to this rule (soybean, cottonseed, canola, corn germ Read More. Vegetable oil extraction-offers vegetable oil extraction Vegetable oil extraction is using solvent to extract oil from oil cake, for different capacity , vegetable oil extraction machine and vegetable oil extraction … Read More. Recommend News

sunflower, cottonseed, other oil seeds and oil in cakes like mustard cake, groundnut cake and friendly and generate less effluent. The level Page 1 of 8 bran. output The plants quantity and are ergonomically quality, operator the collets generated from the expander. Solvent Extraction Process The process of solvent extraction results into this purpose. These plants are more efficient

SOLVENT EXTRACTION PLANT PROCESS FLOW DIAGRAM

Sliding Cell Extractor Seed Crushing and Extraction

Extraction of sunflower oil using ethanol as solvent

Sunflower meal is the by-product of the extraction of oil from sunflower seeds. In terms of production, it is the 4th most important oil meal after soybean meal, rapeseed meal and cottonseed meal (Oil …

FOOD TECHNOLOGY pods.dasnr.okstate.edu

Edible oils and fats are produced either by solvent or mechanical extraction of oilseeds or oil-bearing plant and animal materials or by heat rendering of animal tissues.

Process optimisation in sunflower oil extraction by

Small-scale oil extraction is more commonplace in other parts of the world; thus many of the useful resource materials and much of the appro-priate-scale machinery come from other countries. This publication describes the basic process, with additional details on producing oil from sunflower seeds and sources for additional information. Getting Started Consultant E. Peter Matthies has been

Sunflower processing technique Home – Springer

Sunflower Processing Processing of Oil Seed and None-oil seed

22 REGULATORYAFFAIRS ARTICLE January 2004 Volume 15 (1

The crude oil obtained either from expellers or solvent extraction plant contains impurities, which must be removed to make the oil edible, more palatable and stable against rancidity upon storage. The process of removing these impurities is called refining.

PRINCIPLES OF OIL EXTRACTION Biogas

FOOD TECHNOLOGY pods.dasnr.okstate.edu

Extraction of sunflower oil using ethanol as solvent.pdf

The production process of vegetable oil involves the removal of oil from plant components, typically seeds. This can be done via mechanical extraction using an oil mill or chemical extraction …

Process optimisation in sunflower oil extraction by

The production process of vegetable oil involves the removal of oil from plant components, typically seeds. This can be done via mechanical extraction using an oil mill or chemical extraction …

FOOD TECHNOLOGY pods.dasnr.okstate.edu

(PDF) PARAMETERS INFLUENCING THE SCREW PRESSING PROCESS

solvent extraction plant process flow diagram note: soybean oil sunflower oil rape seed oil canola oil sesame oil general line soybean seed sunflower seed rape seed canola seed sesame seed crushing dehulling cooking flakes cooling & bagging extractor expander / extruder dtdc recovered solvent extracted soybean / sunflower/ rapeseed / canola / sesame oil doc (cake) cooling / bagging

Sunflower Processing Processing of Oil Seed and None-oil seed

Project Profile msmedi-agartala.nic.in

SUNFLOWER OIL EXTRACTION USING SUPERCRITICAL FLUIDS

1/05/2014 · This could be plant material that has no known antimicrobial effect (for example, a carrier oil such as sunflower oil) at the testing stage. FIGURE 1. Diagram of Soxhlet extraction equipment.

Oil Presses Embrapa

process, or expression, involves the use of mechanical power to remove oil from the seed, such as batch hydraulic pressing and continuous mechanical pressing (screw presses). Chemical processes, or extraction, are based in solvent extraction.

Project Profile msmedi-agartala.nic.in

SUNFLOWER SECTOR DEVELOPMENT STRATEGY 2016-2020

Desmet Ballestra, a leader in oil extraction technologies. P A T E N T I S S U E D Solvent Extraction The seed, having been properly prepared, is separated into a crude oil fraction and a protein meal fraction by solvent extraction. The extractor utilizes a countercurrent, multi-stage washing with commercial hexane solvent to enable a reasonable quantity of solvent to extract a maximum

Oil Presses Embrapa

rapeseed oil extraction process oil seed press machine

SUNFLOWER SECTOR DEVELOPMENT STRATEGY 2016-2020