cat6e wiring guide

cat6e wiring guide

Category 6e (Cat6e) wiring is an enhanced version of Cat6, offering higher bandwidth and faster data transfer rates, ideal for high-performance networks in homes, offices, and data centers.

It supports up to 10 Gbps over shorter distances, making it suitable for demanding applications like streaming, online gaming, and commercial installations, ensuring reliable and efficient connectivity.

Overview of Cat6e Cable and Its Benefits

Category 6e (Cat6e) cable is an advanced Ethernet cable designed for high-speed data transmission, offering superior performance compared to Cat6. It supports frequencies up to 250 MHz and delivers speeds up to 10 Gbps over shorter distances, making it ideal for demanding network environments. Cat6e cables minimize signal interference due to their enhanced insulation and twisted-pair design, ensuring reliable connectivity. They are versatile, suitable for both residential and commercial installations, and provide future-proofing for evolving network demands, making them a cost-effective solution for modern networking needs.

Importance of Proper Installation for Network Performance

Proper installation of Cat6e cables is critical to ensure optimal network performance. Incorrect wiring or poor cable management can lead to signal interference, reduced bandwidth, and slower data transfer speeds. Cat6e’s advanced capabilities, such as 10 Gbps speeds, can only be fully realized with precise termination and routing. Improper installation may result in frequent disconnects, packet loss, and compromised network reliability. Therefore, adhering to installation best practices is essential to maximize the cable’s potential and maintain a stable, high-speed connection for all devices on the network.

Cat6e Wiring Diagram and Standards

Cat6e wiring diagrams and standards ensure proper cable organization and connectivity. They define wire pair arrangements for compatibility and optimal network performance, supporting high-speed data transmission.

T568A and T568B Wiring Standards

T568A and T568B are the two primary wiring standards for Ethernet cables, including Cat6e. They define the specific arrangement of wire pairs within RJ45 connectors. T568A is commonly used in the U.S., while T568B is widely adopted in telecommunications. Both standards ensure compatibility and proper signal transmission. The key difference lies in the order of the green and orange wire pairs. T568A places the green pair on pins 1 and 2, while T568B places the orange pair there. Consistency is crucial, as mixing standards can cause connectivity issues. Both support high-speed data transmission, making them ideal for Cat6e installations.

Understanding Color-Coded Wire Pairs

Cat6e cables consist of four twisted wire pairs, each color-coded for easy identification. The pairs are orange (white/orange), green (white/green), blue (white/blue), and brown (white/brown). Each pair serves a specific function in data transmission, with the coloring ensuring consistent wiring. The twisting of pairs minimizes electromagnetic interference (EMI), enhancing signal integrity. Understanding these color codes is essential for proper cable termination and maintaining performance. Consistent use of color coding ensures error-free wiring and reliable network connectivity.

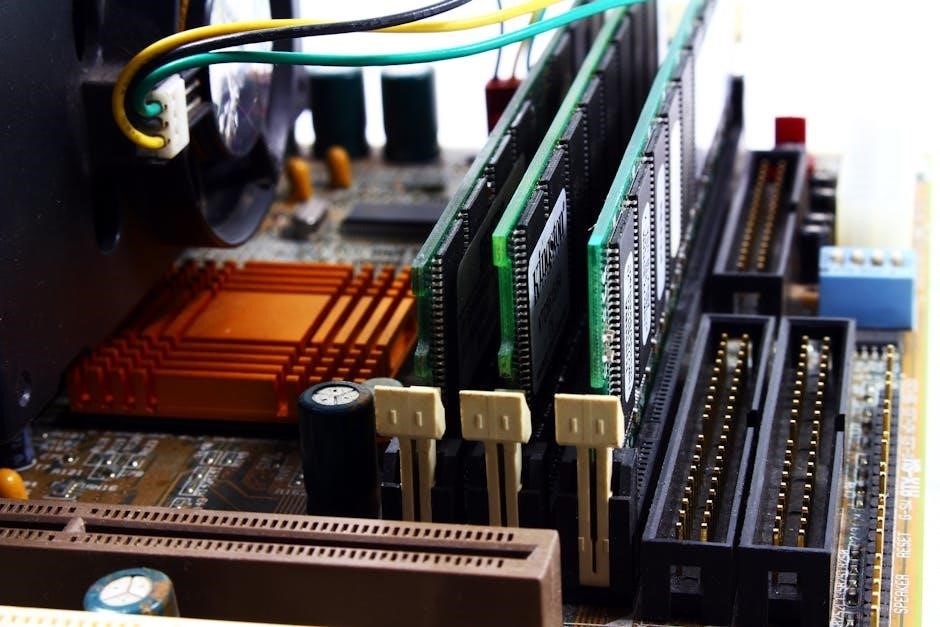

Tools and Materials Required for Cat6e Wiring

Essential tools include a crimping tool, cable tester, and cable stripper. Materials needed are Cat6e cable, RJ45 connectors, and patch panels for clean installations.

Essential Tools: Crimping Tool, Cable Tester, and More

A crimping tool is vital for securely attaching RJ45 connectors to Cat6e cables. A cable tester ensures proper connectivity by verifying all wires are correctly terminated. Additional tools include a cable stripper for removing outer jackets and a punch-down tool for patch panel installations. Cable organizers and label makers are optional but helpful for maintaining a tidy setup. These tools collectively ensure a professional and reliable Cat6e wiring installation.

Materials Needed: Cat6e Cable, RJ45 Connectors, etc.

The primary materials required for Cat6e wiring include high-quality Cat6e cables, which feature four twisted pairs of copper wires. RJ45 connectors are essential for terminating the cables into network devices. Additionally, a patch panel may be needed for organizing multiple connections in a central location. Cable ties and labels are useful for managing cables neatly. Optional materials include faceplates and wall jacks for in-wall installations. These components ensure a robust and organized network setup.

Step-by-Step Installation Guide

Start by gathering all necessary tools and materials. Carefully strip the Cat6e cable, untwist the wire pairs, and arrange them according to your chosen wiring standard for efficient installation.

Step 1: Gather Tools and Materials

To begin the Cat6e wiring process, ensure you have all necessary tools and materials. These include a high-quality Cat6e cable, RJ45 connectors, a crimping tool, and a cable tester for verification. Additionally, you may need cable ties, a cable stripper, and a wire cutter for precise wire management. Organize these items in a workspace to streamline the installation process and avoid delays. Proper preparation is key to achieving a professional and efficient network setup.

Step 2: Strip the Cable and Prepare Wires

Using a cable stripper, carefully remove approximately 1.5 inches of the outer jacket from the Cat6e cable, exposing the four twisted wire pairs. Be cautious not to cut or damage the inner wires during this process. Once stripped, gently separate the wires while maintaining their twist to prevent signal interference. This step ensures proper wire arrangement for the next stages of termination; Properly preparing the wires is essential for achieving a reliable and high-performance network connection.

Step 3: Untwist, Arrange, and Trim the Wires

After stripping the cable, carefully untwist each pair of wires, ensuring minimal disruption to their natural twist. Arrange the wires according to the chosen standard (T568A or T568B), matching the color-coded pairs to the correct positions. Once arranged, trim the excess wire ends to a uniform length, leaving enough to fit into the RJ45 connector; Proper alignment and trimming are critical for maintaining signal integrity and achieving optimal network performance. This step ensures the wires are correctly positioned for termination.

Termination and Testing of Cat6e Cables

Proper termination ensures optimal performance, while cable testing verifies connectivity and speed. Use a cable tester to confirm all wires are correctly connected and functioning as intended.

How to Terminate Cat6e Cables Correctly

Terminating Cat6e cables requires precision to ensure optimal performance. Begin by stripping 1.5 inches of the outer jacket, exposing the twisted pairs. Carefully untwist the wires and arrange them according to the T568A or T568B standard. Trim the excess wires to the same length, leaving about 0.5 inches for the connector. Insert the wires into an RJ45 connector, ensuring proper alignment. Use a crimping tool to secure the connector firmly. Finally, test the cable with a network tester to verify all connections are functioning correctly.

Testing the Cable with a Network Cable Tester

After terminating the Cat6e cable, use a network cable tester to verify its functionality. The tester checks for connectivity, ensuring all eight wires are correctly mapped. It detects issues like open circuits, short circuits, or miswired pairs. Simply plug the cable into the tester at both ends and run the test. A successful test confirms proper termination and ensures reliable network performance. This step is crucial for troubleshooting and guaranteeing the integrity of your Cat6e installation.

Best Practices and Common Mistakes to Avoid

Best practices include maintaining cable organization, avoiding tight bends, and proper termination. Common mistakes include untwisting wires excessively, using incorrect wiring standards, and not testing the cable.

Optimizing Cable Placement for Signal Integrity

Proper cable placement is crucial for maintaining signal integrity in Cat6e wiring. Avoid routing cables near power sources or electrical interference to minimize noise and degradation. Use cable management tools like raceways or conduits to keep wires organized and protected. Ensure cables are not bent at tight angles, as this can disrupt data transmission. Additionally, label all cables clearly to simplify troubleshooting and future updates. By optimizing cable placement, you can ensure reliable high-speed performance and extend the lifespan of your network infrastructure.

Avoiding Common Errors in Cat6e Wiring

To ensure a reliable network, avoid common mistakes during Cat6e wiring. Incorrect wire pairing, insufficient stripping of the jacket, and improper crimping are frequent errors that can degrade performance. Always follow T568A or T568B standards to maintain consistency. Avoid over-twisting wires, as this can introduce signal loss. Additionally, ensure all connections are securely crimped to prevent loose contacts. Testing each cable with a network tester after termination can identify issues early, saving time and ensuring optimal network functionality. Attention to detail is key for a flawless installation.